Protect You Engine from Harm You Can’t See.

You’re enjoying the car scene and even maybe racing. Along the way you’re likely adding performance upgrades and learning many things from observation and experience. Some problems, such as vibration, aren’t so obvious and it can be costly without the right harmonic damper.

Understanding crankshaft torsional vibration and installing a proper harmonic damper are building blocks of long lasting engine performance. In this post we’ll de-mystify it and explain why. Then check out how to find your Fluidampr performance damper and locate a dealer.

Fluidampr (a division of Vibratech TVD) is an established OEM harmonic damper manufacturer for factory race teams and high performance models, plus the automotive aftermarket and performance racing industry. You’ll find Fluidampr protecting engines at the highest professional levels of endurance racing down to grassroots racing and street performance.

What Is Torsional Vibration?

Torsional vibration is the end-to-end twisting motion of the crankshaft. Each time a cylinder fires the force flexes the crankshaft ahead of its natural rotation. Then it rebounds. The greater the force, the greater the vibration amplitude. In succession, a vibration frequency sets up related to RPM.

On its own torsional vibration contributes to metal fatigue. It’s particularly catastrophic when frequency matches resonance of the rotating assembly. Amplitude magnifies when frequencies match and the crankshaft may snap. A classic example of resonance is a glass shattering when a singer hits the right pitch.

Torsional vibration is not the only vibration occurring in the engine. You may also experience an imbalance or rotational vibration caused by unmatched reciprocal weight. Axial balance is controlled by thrust bearings and main caps. Last, torsional vibration can not be adjusted for on a balancing machine because it is caused by combustion.

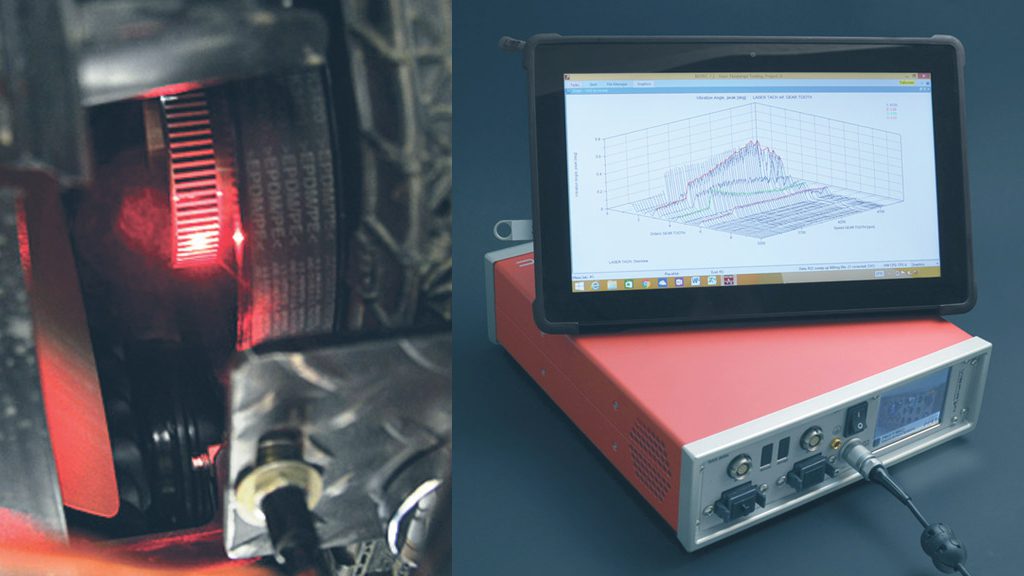

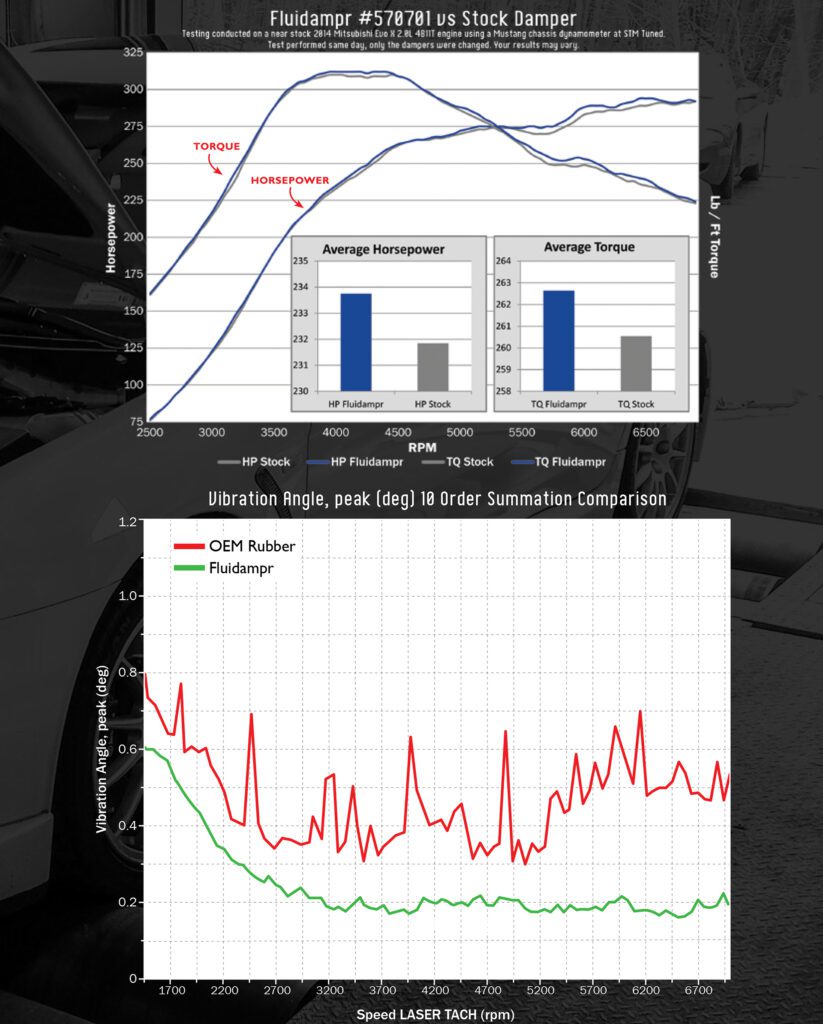

Fluidampr measures crankshaft torsional vibration with an optical sensor and FFT analyzer during a dyno engine sweep.

Types of Engine Vibration

-

🔄 Torsional = crankshaft twisting and rebounding

-

↕ Axial = crankshaft front-to-back movement

-

⚖ Unbalanced = rotating weight mismatch

It is the job of the harmonic damper to control torsional vibration.

Vibration 101 – Key Terms

- Vibration

Oscillatory motion of engine components, often caused by imbalance, combustion forces, or mechanical interactions. - Frequency

The rate at which a vibration occurs, measured in hertz (Hz), or cycles per second. - Amplitude

The magnitude of vibration displacement, typically measured in degrees (for torsional vibration) or linear distance. - Resonance

A condition where vibration frequency matches a system’s natural frequency, causing a sharp increase in amplitude and potential damage.

“People look at crank pulleys and go, ‘Okay, it bolts on, we’re good to go.’ But there’s a lot more that goes into it. The harmonics of the engine affect so much.”

– Jimmy Oakes. Jimmy Oakes Garage

Why Torsional Vibration Gets Worse With Performance Modifications

The basic understanding of the types of engine vibration above is important when you begin to make performance modifications.

Generally, a cold air intake and exhaust are the first steps for DIY modifications. Followed by force induction, injectors and power boosters. Maybe higher octane gas. Definitely a tune. With these modifications you’re adding more air and fuel, which in turn generates more torque and more force on the crankshaft. Torsional vibration amplitude will go up as a result. (Heat will too and cooling system upgrades are worth researching.)

You may also build quicker throttle response by installing lightweight rotating assembly components. Perhaps a single mass flywheel, rods and pistons, or even the crankshaft itself. Doing so will change the rotating assembly resonance frequency.

How Torsional Vibration Damages Engines

Inline 4 crankshaft failure caused by uncontrolled torsional vibration

If great enough, torsional vibration will damage your engine when left uncontrolled. Over time it will accelerate wear on components. Worse case is catastrophic failure.

Failure Isn’t Always Instant – But It’s Inevitable

Most associate torsional vibration with a quick crankshaft snap. While that’s true, a more likely scenario is failure by fatigue.

Visual Signs It May Be Torsional Vibration

- Timing misfire. Getting a timing error code? Consider the crankshaft torsional whip is great enough that it throws the timing sensor off.

- Excessive main bearing wear.

- Torsional vibration metal-to-metal pass through.

- Timing gear and chain wear.

- Oil pump failure. Increasing horsepower already puts a high demand on the oil system. In addition, oil pump gears may be susceptible to increased vibration.

- Accessory drive brackets breaking or bolts backing out.

Why a Fluidampr Performance Harmonic Damper Is A Smart Upgrade For Modified Engines.

The stock harmonic balancer is tuned for a narrow frequency range and factory power. Performance modifications will overwork it or negate its tune. A tell-tale DIY sign of overworking is cracked, bulging or missing rubber between the hub and inertia ring. If not upgraded the ring may separate and cause engine bay damage and even a safety risk at the track.

Crack, missing or bulging rubber is an early warning sign that the stock harmonic damper should be upgraded to a Fluidampr performance damper.

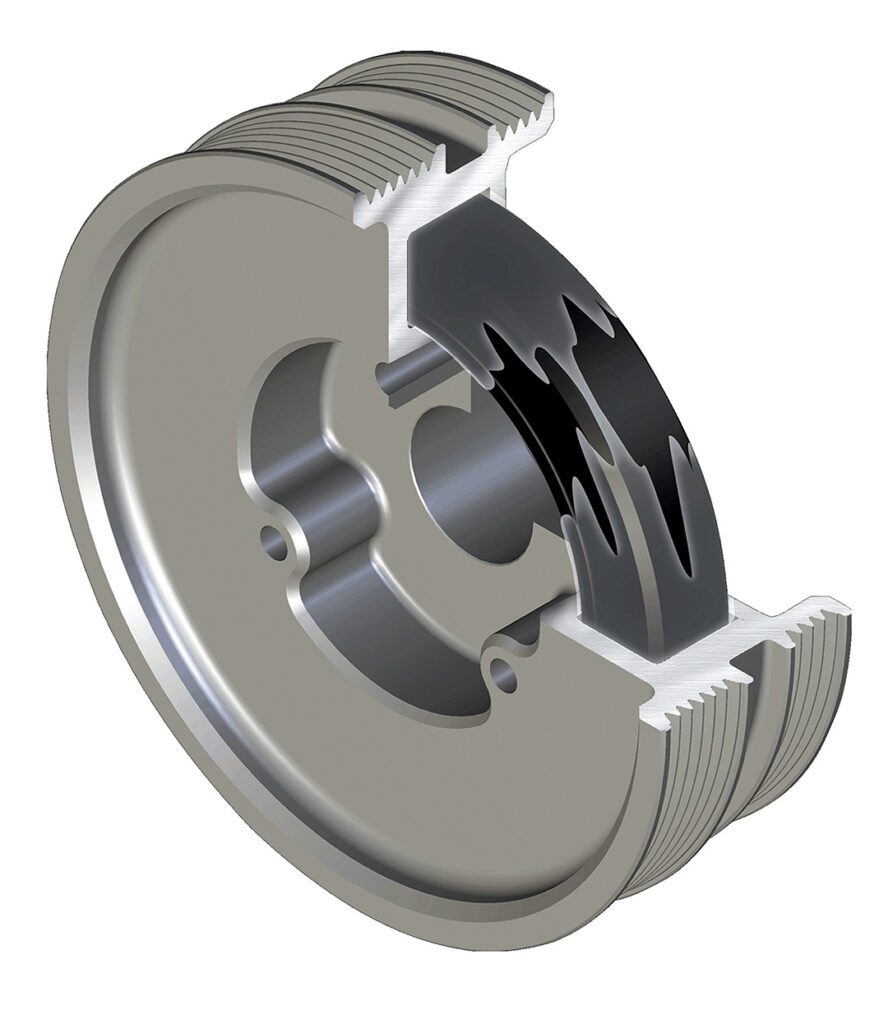

What Makes A Fluidampr Performance Harmonic Damper Different

Fluidampr is a viscous type damper. A viscous damper controls torsional vibration different than a stock elastomer harmonic damper. Inside a sealed housing the inertia ring shears through silicone in real time response to vibration amplitude. Shearing transforms vibration to heat that radiates through the housing. The design provides several key advantages including being more effective the harder it works, thermal stability, and no tuning required. A Fluidampr performance damper will also last the life of the engine with no rebuilds or retuning.

Find your Fluidampr performance damper and a dealer.

A Fluidampr performance damper contains an internal inertia ring that shears through a thin layer of viscous silicone inside a sealed housing.

“The only rule is they all get a Fluidampr, and that’s about it.”

– Stephan Napp. Napp Motorsports.

Tested & Trusted Across Motorsports

Fluidampr is SFI 18.1 spec and has been race proven since its motorsports inception in 1985.

Build Profiles That Should Upgrade

| Build Type | Example Engines | Why Upgrade to Fluidampr |

|---|---|---|

| Daily Driver | LS, LT4, Coyote, Cummins, Power Stroke, Duramax | Smoother ride. Prolong engine life. Set foundation to build up performance. |

| Bolt-On Daily Drivers | WRX, Mustang GT, Charger R/T | Reduces added harmonic stress from bolt-ons and helps protect aging components. |

| Restomod Muscle Cars | SBC, BBC, Crate LS | Balances modern powertrain upgrades with classic chassis. Reduces NVH and vibration wear. |

| Engine Swap Projects | LS in Miata/240SX, Barra in Foxbody | Smooths out vibration from mixed engine/chassis setups. Improves NVH and longevity. |

| Turbocharged Street Builds (400–700 HP) | 2JZ-GTE, LS1, K24 Turbo | Controls vibration from increased cylinder pressure and boost. Improves drivability and protects rotating assembly. |

| Tuned Diesel Trucks | Cummins 5.9L/6.7L, Duramax, Power Stroke | Controls low-RPM vibration and protects the rotating assembly during towing or heavy tuning. |

| Stroker Engine Builds | 383 SBC, 408 LS, 3.4L 2JZ | Controls extra torsional loads from long-stroke cranks. Protects crankshaft and bearings. |

| High-RPM Naturally Aspirated Track Cars | Honda S2000, K-Series, LS7 | Reduces torsional harmonics at high RPMs to protect bearings and valvetrain components. |

| Drift Cars | 2JZ, LS3, SR20DET | Absorbs violent harmonic spikes from clutch kicks and throttle transitions. Increases engine reliability. |

| High-Horsepower Drag Builds | Hemi, 2JZ with Big Turbo, BBC | Handles massive torque spikes under launch. Prevents crankshaft twist and damage. |

| Road Racing & Time Attack | LS7, B18C, Coyote 5.0 | Maintains harmonic control at sustained RPM. Improves reliability in endurance applications. |

| Pro-Level Race Engines | IMSA, NHRA, Formula Drift builds | Race-proven durability. SFI-certified and trusted by professional engine builders worldwide. |

Fluidampr performance damper p/n 700232 installed on a twin turbo Ford 5.0L Coyote.

Myth Busting: “Only Race Cars Need Them”

While you’ll see Fluidampr performance dampers on race cars, they also perform exceptionally well on daily drivers and street builds. While some may say they’re overkill, many diesel truck owners purchase to enjoy a smoother drive while towing a trailer. Improved torsional vibration control also leads to prolong engine life and higher quality builds. This is why you’ll find non-SFI spec viscous type dampers as original equipment on luxury vehicles, plus hypercars, and even work trucks. It should be noted, OEM viscous dampers are not intended or rated for motorsports and will not withstand the abuse like a Fluidampr performance damper will.

Drive Hard. Stay Protected.

Now you know what you don’t see about making engine performance reliable. Vibration and harmonic dampers are key knowledge professional race engine builders stake their reputation and championships on.

Find your Fluidampr performance damper and a dealer.