By Brian Wagner

DRAGZINE.COM

There’s nothing like the sound or power a large displacement engine can make, the throaty tone is unmistakable and so are the fast elapsed times they can produce. Part of having a happy big block is making sure the rotating assembly is balanced correctly with the proper harmonic balancer. Nick Orefice from Fluidampr goes over why you need a good balancer for your big block Chevy, Mopar, and Ford FE mill.

Any size engine is going to produce a certain amount of vibration and it’s the job of the harmonic balancer on the front of a crankshaft to keep it under control. A big bock engine might not turn the same amount of RPMs you see in a small block, however, the vibrations produced by its rotating assembly can be just as destructive.

“Big block drag racing engines put down a lot of power through shear displacement and a long stroke. The stock elastomer harmonic balancer, and some aftermarket designs, are only tuned to mitigate the worst harmonics in a narrow frequency band (typically 50Hz) under stock conditions. A drag racing engine is anything but stock, various combinations of rotating assembly parts weight and sizes will produce different frequencies. A quality broad range harmonic balancer is the preferred choice to keep vibrations under control,” Orefice explains.

Besides having the right balancer for the job, you need to make sure it fits correctly on the crankshaft. Many big-block engines have a press-fit style harmonic balancer, and it’s a good idea to check for issues if the balancer has been removed.

“On these engines, a proper press fit is how vibration is transmitted to the balancer, this allows the balancer to do its job. If you repeatedly remove and install the harmonic balancer it will wear down the press fit. It’s recommended to check it each time the balancer is installed. A proper press fit is 0.0005” – 0.0015” between the inner diameter of the balancer and outside diameter of the crank snout. If the fit measures outside of tolerance, then replace the balancer, or balancer hub if it’s removable from balancer ring,” Orefice says.

If you’re putting together a rowdy big block it would be a good idea to use a worthy harmonic balancer. Orefice explains what you need to look for in a harmonic balancer when you’re rocking a whole lot of cubic-inches.

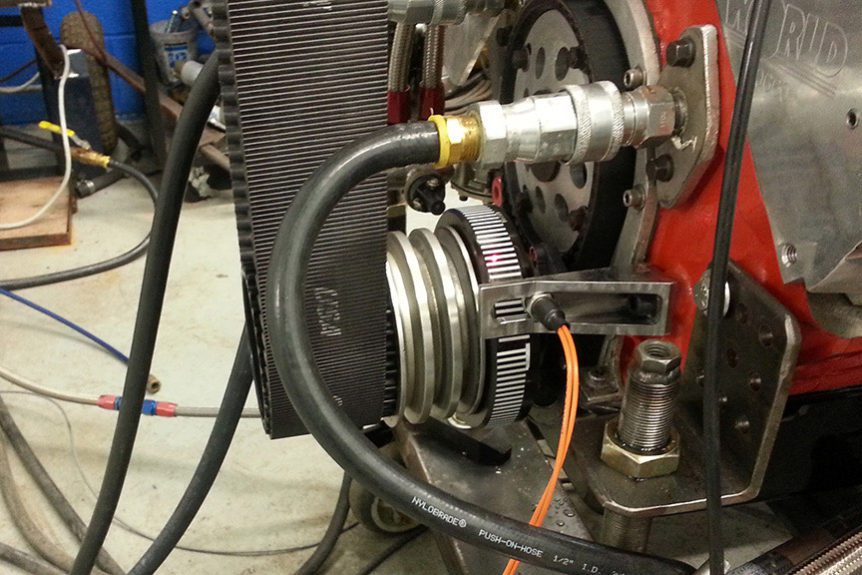

“Fluidampr harmonic balancers are rated SFI 18.1 spec for structural integrity. Beyond the safety standard required for most drag racing sanctioning bodies, the outer housing of a Fluidampr performance damper is a robust, laser-welded design that holds up to high torque and horsepower stress. Inside a Fluidampr is an un-bonded inertia ring that shears through a thin layer of viscous silicone, so no tuning or maintenance is required. These quality design features provide for a superior lifespan and optimum vibration control across the rpm range.”

Read Full Article @ Dragzine.com